Transmission Repair

CERTIFIED Mechanics

CERTIFIED Mechanics

CERTIFIED Mechanics

Auto Transmission Repair

Positioned between the engine and the wheels is your car’s transmission. The transmission receives the energy generated by the engine and adapts that power to provide the proper torque to the wheels for the given driving conditions. There are two main types of transmissions, manual and automatic, although a couple new hybrids have also appeared over the last few years.

Your check engine light may indicate a transmission problem, as does a fluid leak, commonly red, that can come from a bad gasket or seal. The leak may also accompany a burning smell when it falls on the hot engine. More specific signs to the transmission include noticeable changes in shifting or holding gears. You may notice your engine running a little higher between gears. Of course, grinding or groaning noises associated or timed around gear changes can also be an indication of transmission problems.

For manual transmissions, you may notice some difficulty moving the gear shift into gear or feel the clutch sticking.

If you notice some noises or issues when shifting gears, quick action can minimize more significant costs. Call Ohio Autocare. We have highly trained and experienced transmission repair mechanics that can diagnose your transmission problem and get you quickly back on the road.

Auto Transmission Repair & Service

For Manual and Automatic Transmission Service and Repair, Call the Ohio Autocare near you, or click the auto shop below for our convenient online scheduling app.

Automobile Transmissions

AUTOMOBILE TRANSMISSIONS

The first cars were single-gear engines and didn’t go fast enough to need a second gear, but the blueprint for gear-driven combustible engines was already being developed. Just as automobile technology advancement was growing, patents were already on the books for variable geared bicycles. While much simpler, the bicycle gears used the same gear ratio principle that would be adopted by the automobile industry.

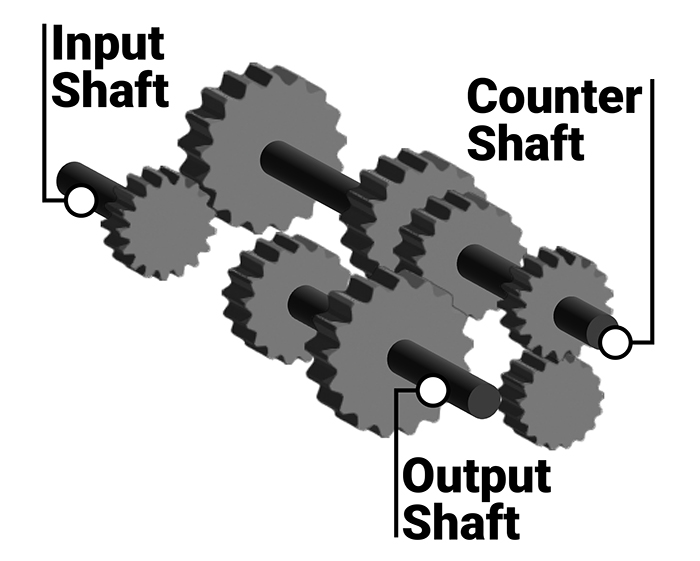

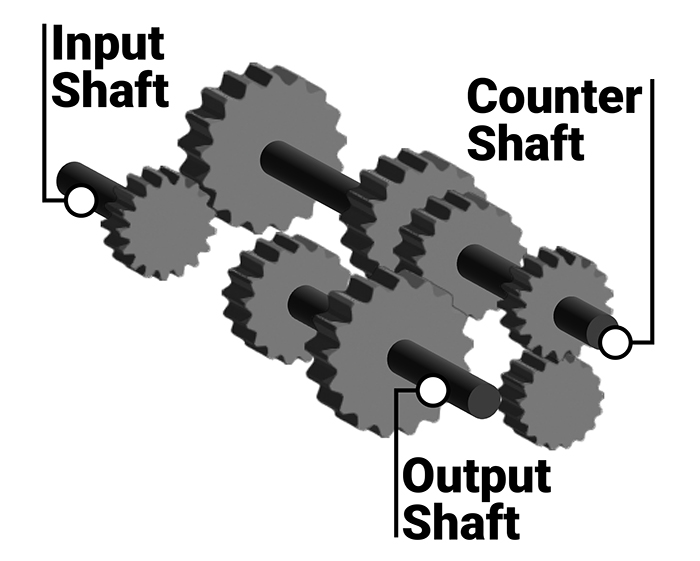

When you start your car, the engine powers up with the force of the pistons turning the crankshaft to create rotational power. Besides turning the drive belt, timing chain, and power steering belt, the crankshaft also turns the flywheel which is attached to the clutch plate and pressure plate of the transmission. Protruding from the pressure plate is the input, or main drive, shaft that leads into the gear box. Within the gear box, the input and output shafts has multiple gears of variable diameters and lined up across the counter shaft which also has variable diameter gears. The gear ratio principle has remained the basis for transmissions since the early days of the automobile, but how the gears are changed has seen the most innovation and is dependent on the type of transmission in the vehicle.

MANUAL TRANSMISSIONS

When a car is first started, it is likely in Park or Neutral. The engine turns over and begins to run in its idle speed. The car doesn’t go anywhere because the power the engine is producing is disengaged from the gears of the transmission. To get the car moving, the driver must shift the car into gear so the engine power gets transferred to the wheels and moves the car forward (or backward).

When a car is first started, it is likely in Park or Neutral. The engine turns over and begins to run in its idle speed. The car doesn’t go anywhere because the power the engine is producing is disengaged from the gears of the transmission. To get the car moving, the driver must shift the car into gear so the engine power gets transferred to the wheels and moves the car forward (or backward).

Compared to today’s complex transmissions, early cars were typically outfitted with an unsynchronized sliding gear transmission. This transmission system was difficult to shift and required the driver to attempt to match the engine RPMs with the accelerator for the next highest gear. The greater the difference in gear RPMs resulted in more damaging grinding and gear wear.

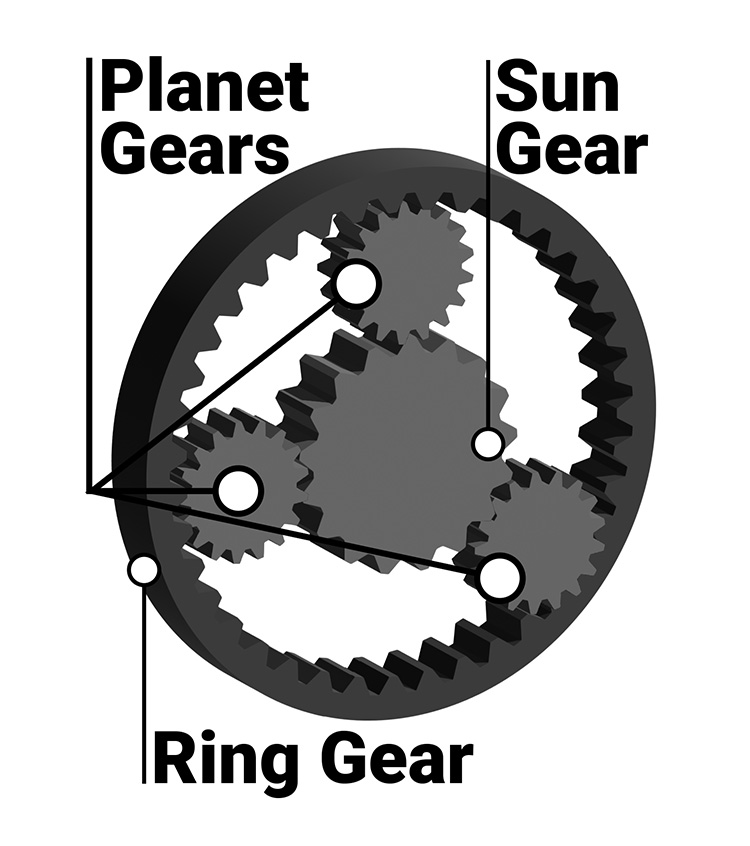

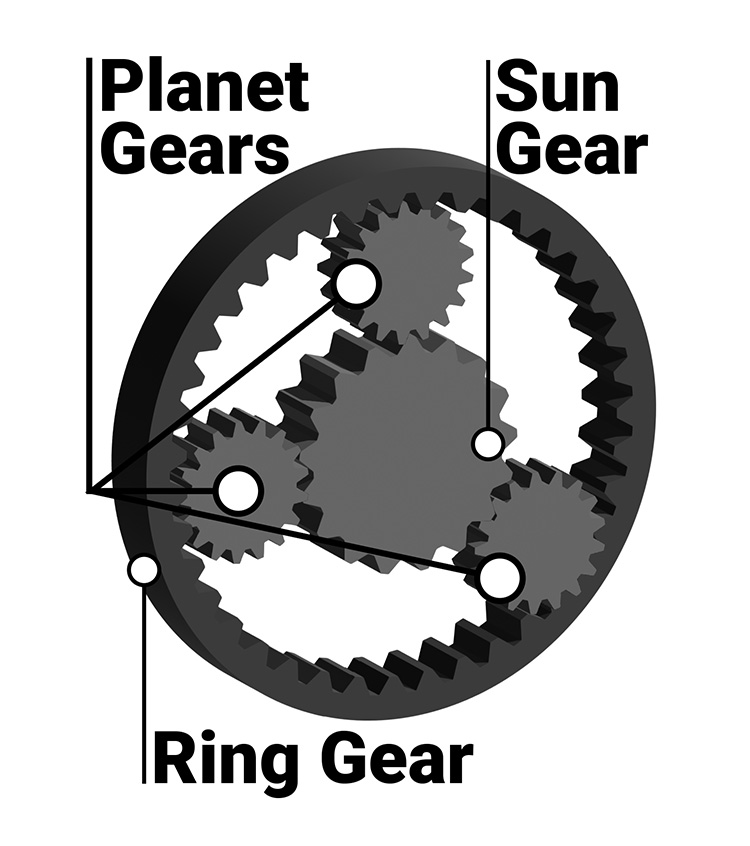

When Ford introduced the Model T, it featured an existing transmission design called a Planetary Gear System and was one of the vehicles more popular features. The Planetary Gear Transmission had a central Sun gear with three smaller “planet” gears surrounding it and held in orbit by the ring gear. To obtain the desired gear ratio, one gear would be locked to the ring gear while the other two planet gears were disengaged and freely spinning to the chosen gear’s speed. With the gears constantly in contact with the Ring and Sun gears, this greatly simplified shifting gears and was widely popular for a couple decades and would eventually evolve into the first Automatic Transmissions.

But the sliding shaft gear transmissions from the early cars were about to make the first of two big comebacks. Before the Model T stopped production in the late 20’s, most cars had converted back to the sliding shaft gear and nearly all cars manufactured before World War II featured this transmission type.

AUTOMATIC TRANSMISSIONS

With the difficulty of early manual transmissions, automobile manufacturers spent decades working on a more driver-friendly solution. A form of automatic transmission existed as far back as the early 1900’s from the United Kingdom with the introduction of the Planetary Gearset. but the first line-manufactured vehicle was the four-speed General Motors Hydramatic.

The Hydramatic still had the set of variable gear ratios but used hydraulics along with a Torque Converter and a series Brake Bands and Clutches to automatically switch gears depending on the amount of pressure applied to the hydraulic fluid by the engine.

When cars hit the computer age, the hydraulics were replaced with computer sensors that could analyze power fluctuations and adapt the gears automatically.

Automatic Transmissions were very popular in the United States and by 1957, over 80% of the US cars were automatic and was over 97% by 2020. Some manufacturers even dropped manual transmission vehicles from their line. For the rest of the planet, though, not so much. By the end of the 20th century, only about 10% of European cars had automatic transmissions and around 50% globally.

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

One of the more recent innovations in automatic transmissions is the Continuously Variable Transmission.

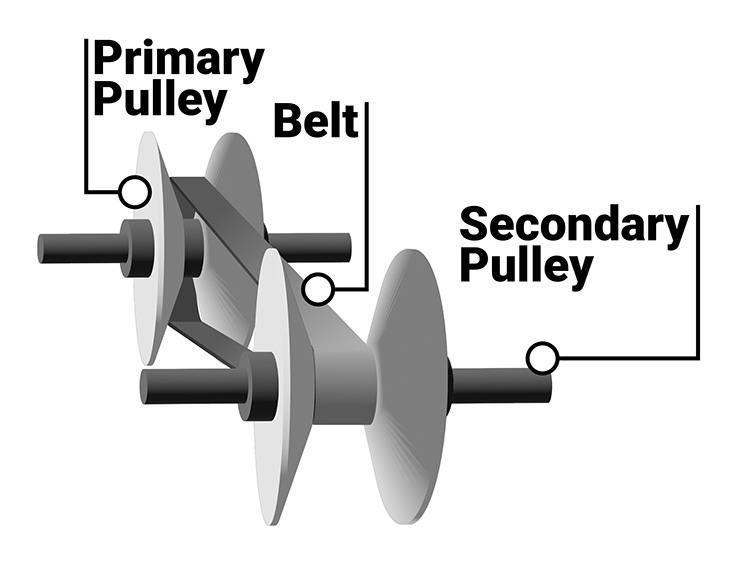

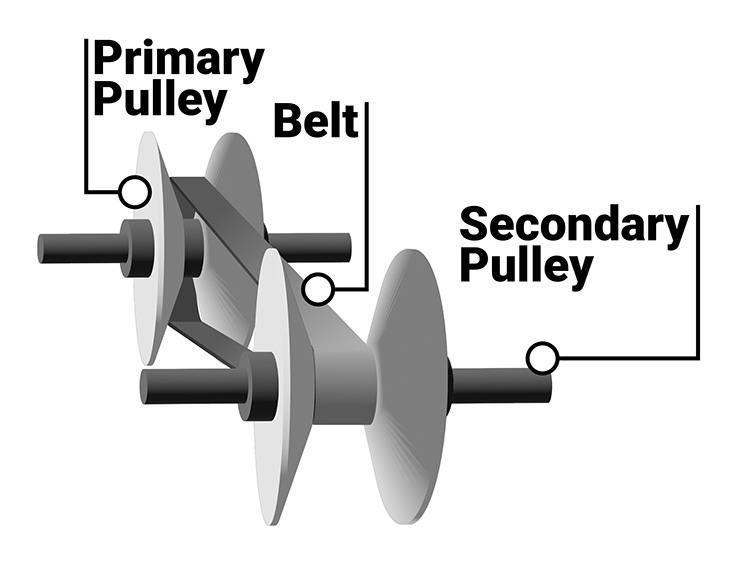

Instead of a series of precisely sized gears, the CVT operates with two pullies connected by a chain or belt. As the driving conditions change, the two pulleys adapt the depth at which the chain or belt circumvents its center diameter to achieve exponentially more gear ratios.

In addition to being lighter, the CVT has virtually imperceptible noise or motion changes associated with changing gears.

AUTOMOBILE TRANSMISSIONS

The first cars were single-gear engines and didn’t go fast enough to need a second gear, but the blueprint for gear-driven combustible engines was already being developed. Just as automobile technology advancement was growing, patents were already on the books for variable geared bicycles. While much simpler, the bicycle gears used the same gear ratio principle that would be adopted by the automobile industry. When you start your car, the engine powers up with the force of the pistons turning the crankshaft to create rotational power. Besides turning the drive belt, timing chain, and power steering belt, the crankshaft also turns the flywheel which is attached to the clutch plate and pressure plate of the transmission. Protruding from the pressure plate is the input, or main drive, shaft that leads into the gear box. Within the gear box, the input and output shafts has multiple gears of variable diameters and lined up across the counter shaft which also has variable diameter gears. The gear ratio principle has remained the basis for transmissions since the early days of the automobile, but how the gears are changed has seen the most innovation and is dependent on the type of transmission in the vehicle.MANUAL TRANSMISSIONS

When a car is first started, it is likely in Park or Neutral. The engine turns over and begins to run in its idle speed. The car doesn’t go anywhere because the power the engine is producing is disengaged from the gears of the transmission. To get the car moving, the driver must shift the car into gear so the engine power gets transferred to the wheels and moves the car forward (or backward).

Compared to today’s complex transmissions, early cars were typically outfitted with an unsynchronized sliding gear transmission. This transmission system was difficult to shift and required the driver to attempt to match the engine RPMs with the accelerator for the next highest gear. The greater the difference in gear RPMs resulted in more damaging grinding and gear wear.

When a car is first started, it is likely in Park or Neutral. The engine turns over and begins to run in its idle speed. The car doesn’t go anywhere because the power the engine is producing is disengaged from the gears of the transmission. To get the car moving, the driver must shift the car into gear so the engine power gets transferred to the wheels and moves the car forward (or backward).

Compared to today’s complex transmissions, early cars were typically outfitted with an unsynchronized sliding gear transmission. This transmission system was difficult to shift and required the driver to attempt to match the engine RPMs with the accelerator for the next highest gear. The greater the difference in gear RPMs resulted in more damaging grinding and gear wear.

When Ford introduced the Model T, it featured an existing transmission design called a Planetary Gear System and was one of the vehicles more popular features. The Planetary Gear Transmission had a central Sun gear with three smaller “planet” gears surrounding it and held in orbit by the ring gear. To obtain the desired gear ratio, one gear would be locked to the ring gear while the other two planet gears were disengaged and freely spinning to the chosen gear’s speed. With the gears constantly in contact with the Ring and Sun gears, this greatly simplified shifting gears and was widely popular for a couple decades and would eventually evolve into the first Automatic Transmissions.

But the sliding shaft gear transmissions from the early cars were about to make the first of two big comebacks. Before the Model T stopped production in the late 20’s, most cars had converted back to the sliding shaft gear and nearly all cars manufactured before World War II featured this transmission type.

When Ford introduced the Model T, it featured an existing transmission design called a Planetary Gear System and was one of the vehicles more popular features. The Planetary Gear Transmission had a central Sun gear with three smaller “planet” gears surrounding it and held in orbit by the ring gear. To obtain the desired gear ratio, one gear would be locked to the ring gear while the other two planet gears were disengaged and freely spinning to the chosen gear’s speed. With the gears constantly in contact with the Ring and Sun gears, this greatly simplified shifting gears and was widely popular for a couple decades and would eventually evolve into the first Automatic Transmissions.

But the sliding shaft gear transmissions from the early cars were about to make the first of two big comebacks. Before the Model T stopped production in the late 20’s, most cars had converted back to the sliding shaft gear and nearly all cars manufactured before World War II featured this transmission type.

AUTOMATIC TRANSMISSIONS

With the difficulty of early manual transmissions, automobile manufacturers spent decades working on a more driver-friendly solution. A form of automatic transmission existed as far back as the early 1900’s from the United Kingdom with the introduction of the Planetary Gearset. but the first line-manufactured vehicle was the four-speed General Motors Hydramatic. The Hydramatic still had the set of variable gear ratios but used hydraulics along with a Torque Converter and a series Brake Bands and Clutches to automatically switch gears depending on the amount of pressure applied to the hydraulic fluid by the engine. When cars hit the computer age, the hydraulics were replaced with computer sensors that could analyze power fluctuations and adapt the gears automatically. Automatic Transmissions were very popular in the United States and by 1957, over 80% of the US cars were automatic and was over 97% by 2020. Some manufacturers even dropped manual transmission vehicles from their line. For the rest of the planet, though, not so much. By the end of the 20th century, only about 10% of European cars had automatic transmissions and around 50% globally.