CERTIFIED Mechanics

CERTIFIED Mechanics

CERTIFIED Mechanics

Auto Brake System Inspection & Replacement

Ohio Autocare provides full-service commercial and family fleet automobile brake inspection, installation, and repair for most every make and model of vehicle.

While its important to keep a vehicle in top operating condition, its just as important to be able to stop it once you’ve arrived at your destination. This is the job of the brakes…and its a big job. Stopping one or more tons of kinetic energy moving at 60-70 mph in a few seconds can create a bunch of friction, which leads to wear and tear. While significant advances have been made in the metallurgy and technology of the brake components to extend their lifespan, brake pads, and to a lesser degree brake discs, or rotors, need replaced on occasion.

Brake pad life commonly achieves between 30-70,000 miles, but its dependent upon a variety of factors including driving style, vehicle type, weight, environment as well as the quality of the brake pad, itself. When you hit the brake pedal in a standard automobile, the brake pad deploys against the brake rotor, slowing the vehicle down. Brake rotors experience wear and tear as well, but should last as much as three times longer than a brake pad.

Symptoms of a declining brake system include the common brake “squeak” or grinding noise, shaking steering wheel, and/or the vehicle pulling to the left or right when breaking. If you experience any of these symptoms, call Ohio Autocare for a brake inspection and put a stop to bad brakes.

Brake System Service

For Brake Service & Repair for your family or fleet vehicles, Call the Ohio Autocare near you, or click the auto shop below for our convenient online scheduling app.

Automobile Brakes

Modern automobile brakes have significantly advanced since the wood blocks used on the first cars. Today, disc brakes are a collection of precision components utilizing complex technologies, metallurgies, and physics. Operationally, though, automobile brakes aren’t far removed from the bicycle.

Both systems use pressure applied through a caliper to position a brake pad against a rotating part of the wheel. While the pressure you apply to the bicycle brakes are sufficient enough to stop a couple hundred pounds going 15-20 mph, stopping a 1-2 ton vehicle with 50-70 mph of kinetic energy requires some different engineering. The first cars didn’t go much faster than 10-15 mph, but as car engines became faster, heavier, and more powerful, it didn’t take long for the wooden blocks to become insufficient.

Even at that speed, trips down the undeveloped roadways and trails could be a bone-jarring experience for both machine and beast. Relief came in the form of the pneumatic tire. This allowed for a significantly smoother ride and greater speeds. The wood block brakes were replaced with a softer metal, commonly copper, to minimize damage to the metal wheels. While significantly better, the metal-to-metal screeching was excruciating. Borrowing some earlier innovation from Bertha Benz, brake linings were applied to the metal pads, including rubber, cotton, and asbestos.

Two new brake systems were patented 1902, disc and drum brakes. Both were significant improvements, but the drum brake systems were much more economical with the existing technology and were the adopted standard for half a century.

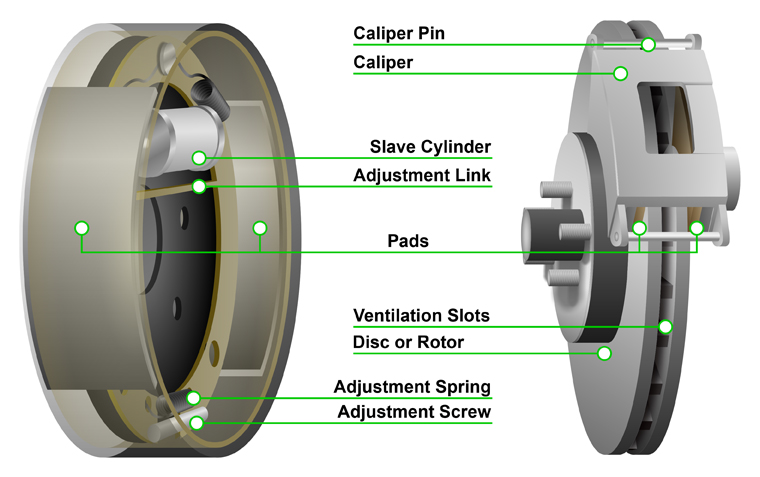

Drum Brake Systems

The round brake drum houses the drum brake system. Inside, two brake shoes are positioned just inside the drum’s sides and matches the drum curve. When the brake pedal is pressed, pistons attached to the brake shoes engage and press the shoes against the sides of the brake drum, slowing the vehicle. A series of springs push the brake pads away from the drum sides when the brake pedal is released by the driver.

Drum brakes were very effective and utilized for decades, some manufacturers still install drum brakes on the rear axles of some models. On all four wheels, though, it was difficult to match the identical pressures on all tires at the same time, leading to mis-aligned shoes and loss of braking effectiveness.

Disk Brake Systems

With advanced manufacturing processes and the advent of hydraulics, disc brakes got another look in Europe in the mid-1950’s. Disc brakes are very similar to bicycle brakes with two brake shoes actuated by a caliper and positioned on either side of the brake rotor. When the brake pedal is pressed, a series of vacuums, hydraulics, and advanced metal alloys provide the near effortless braking we experience today. These systems combine to exponentially magnify the pressure applied to the brake pedal to smoothly bring a multi-ton vehicle to a quick, safe stop. Far removed from early wood and copper brakes, the modern advances in today’s vehicles allow for greater rigidity, capacity, and life span.