Auto Air Conditioning Repair & Service

CERTIFIED Mechanics

CERTIFIED Mechanics

CERTIFIED Mechanics

Auto Air Conditioning Repair

Ohio Autocare has been servicing automobile cooling and air conditioning systems for our neighbors in and near Columbus for over 30 years. We maintain a staff of certified and experienced auto mechanics that can inspect, diagnose and quickly resolve AC issues using modern testing equipment and premium quality NAPA brand replacement parts. Give Ohio Autocare a call when its time for your next air conditioning and cooling service.

While your vehicle’s air conditioning isn’t a critical component of accomplishing its intended function of transportation, steamy Ohio summer roads can make it downright unbearable.

Your vehicle’s air conditioning system is a complex collection of components that work together to cool your car’s interior. A malfunction in any of these components can stop the unit from operating. While its possible a symptom could mean a system replacement, its just as likely its something simple like recharging the system or a clogged filter.

If you notice your air conditioning system not working as efficiently as usual, give Ohio Autocare a call to find the best solution and get you back on the road.

Air Conditioning Service

For Air Conditioning Service & Repair, Call the Ohio Autocare near you, or click the auto shop below for our convenient online scheduling app.

The Automobile Air Conditioner

Our family’s annual road trip growing up was southern Florida and always in August. The first car I remember taking this trip in was Mom’s green Dodge station wagon. It was a 4-door automatic with air conditioning, AM/FM stereo, and a space in the back even Dad couldn’t reach.

The Dodge couldn’t make it one year and we called on Dad’s Plymouth Scamp, a 2-door 3-speed with AM radio, black vinyl interior, and no air conditioning…in Florida…in August. Brutal.

A Dodge station wagon from the early 1970’s.

Early Automobile Air Conditioning

The first automobile air conditioning units appeared in the 1930’s. Installed separately from the production plant, these early AC units were big, bulky, expensive, unreliable, a hit with the wealthy, and discontinued by 1941.

After successfully implementing the installation of air conditioning in the Chrysler Building, Walter Chrysler adapted the technology for use in their vehicles and in 1953 introduced the Imperial as the first production car with optional air conditioning. Very effective, but still a bit pricey. Cadillac, Oldsmobile, and Buick were close behind offering air conditioning units the same year but were, instead, installed separately in the trunk after production.

Modern Automobile Air Conditioning

Finally in 1954, the Nash-Kelvinator Company developed the basis for modern cabin climate control. Launched on their Nash Ambassador model, the fully integrated system not only matched Chrysler’s cooling effectiveness, but added thermostat control along with heating and ventilation. The new system was compact and a fraction of the cost of existing systems. By 1960, nearly 1-in-5 US cars had adopted the new air conditioning system, raising to over 50% just nine years later with significantly higher percentages in the southern states.

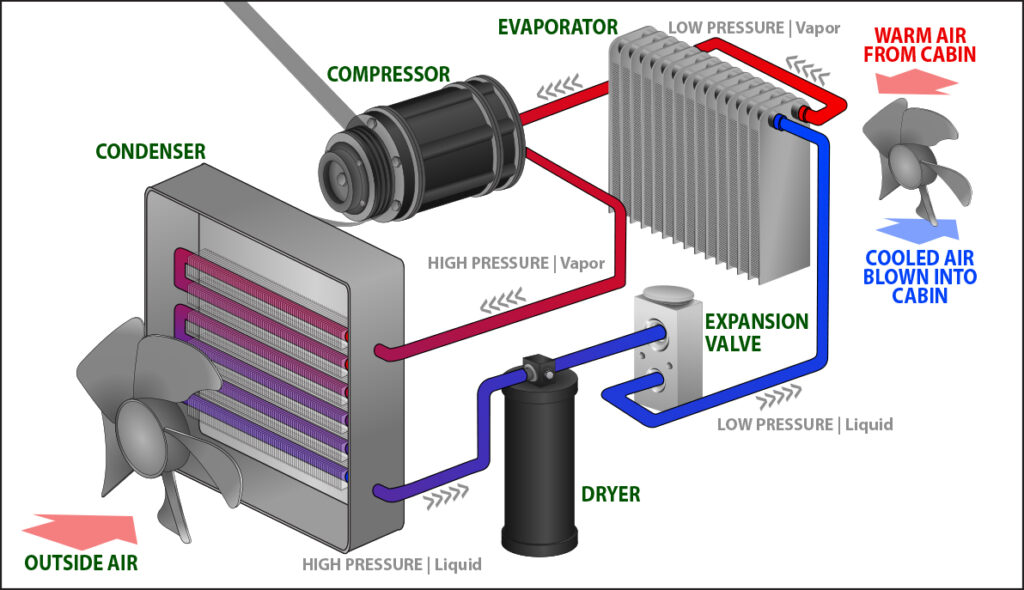

Modern automobile air conditioning units are made up of five main components that are interconnected by a series of pipes and tubing. Running through the tubes is a specially formulated refrigerant that repeatedly transitions between liquid and gaseous states as it cycles through the components.

Compressor

The Compressor is located at the front of most vehicles and one of the components attached to the serpentine belt. As the name implies, the Compressor compresses, or pressurizes, the refrigerant which increases its temperature. This process turns the refrigerant to its liquid state before entering the Condenser on the High-Pressure side of the system.

Condenser

Located on the other side of the vehicle grill, the liquid refrigerant is cooled in the Condenser as the fan blows outside air over the extensive system of condenser fins which had absorbed heat from the refrigerant. As it cools, the refrigerant condenses to a liquid.

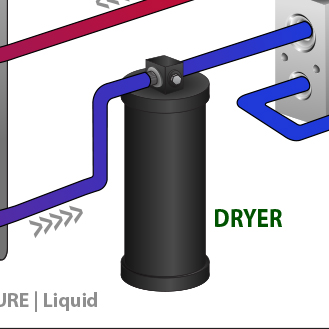

Dryer

Now in liquid form, the refrigerant gets filtered for contaminants and all moisture is removed as it passes through the Dryer before moving on to the Expansion Valve.

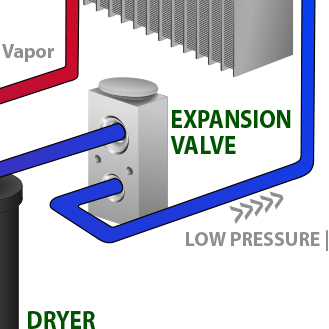

Expansion Valve (or Orifice Tube)

The Expansion Valve receives the High-Pressure refrigerant liquid from the Dryer and relieves the pressure, further lowering the refrigerant temperature and converting the refrigerant to a mist.

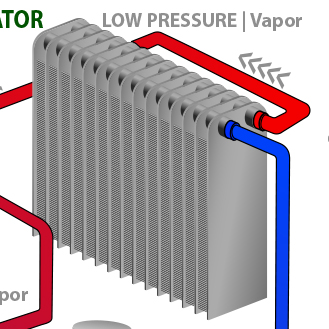

Evaporator

Now on the Low-Pressure side of the system, the cooled refrigerant travels to another radiator-type device called the Evaporator, which is located in the dashboard. The AC refrigerant achieves it’s lowest temperature in the Evaporator. In the car interior, the cabin fans are blowing out cold air. Scientifically, though, the cabin fans of the blower is extracting the humid, hot air from the cabin and blowing that air over the cooled evaporator coils. The refrigerant within the Evaporator absorbs that heat and humidity which results in cool air exiting the vents into the cabin.

The refrigerant absorbs more heat as it moves through the Evaporator and eventually moves on to the Compressor to begin the cycle over again.