Suspension & Steering Service | Reynoldsburg

CERTIFIED Mechanics

CERTIFIED Mechanics

CERTIFIED Mechanics

Suspension & Steering Services | Reynoldsburg

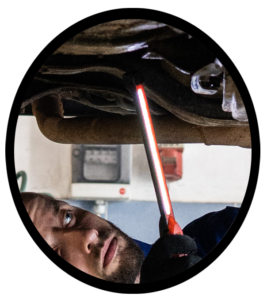

For your next auto steering and suspension service repair, call Ohio Autocare Reynoldsburg. Our trained and certified auto mechanics have extensive experience with virtually all makes and models of cars, trucks, minivans, commercial fleet vehicles and more.

Power Steering Repair & Replacement

Common symptoms of degrading steering components include shaking in the steering wheel, the car pulling to one side while driving, or any squeaking or grinding noises can be indicative of a failing steering system.

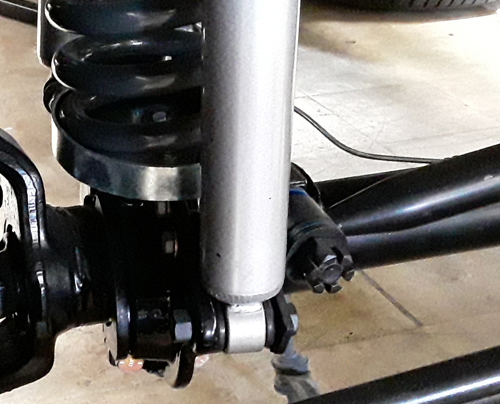

Suspension System Repair & Replacement

While the steering system provides direction control, its connected with the suspension system of your vehicle which provides a smoother ride, but also properly distributes the vehicle weight to safely stabilize the vehicle while driving.

SCHEDULE Suspension & Steering Services

For Suspension and Steering Service & Repair in Reynoldsburg near Brice Road, Call 614-515-2861

Or click the auto shop below for our convenient online scheduling app.