COLUMBUS | Reynoldsburg | Hilliard | CINCINNATI | Loveland

COLUMBUS | Reynoldsburg | Hilliard | CINCINNATI | Loveland

Power Steering Repair & Replacement | Hilliard

CERTIFIED Mechanics

CERTIFIED Mechanics

CERTIFIED Mechanics

Power Steering Repair & Replacement | Hilliard

For your next auto power steering repair, replacement, and service, call Ohio Autocare Hilliard. Our trained, experienced, and certified auto mechanics have extensive experience with virtually all makes and models of cars, trucks, minivans, commercial fleet vehicles and more.

We are a local, family-owned, and BBB-Accredited auto repair shop and have been a trusted resource for honest and economical auto maintenance for Hilliard families and businesses for over 30 years.

We provide full-service repair and replacement of power steering systems for virtually all makes and models of commercial and family vehicles.

- Rack & Pinion Steering

- Tie Rods

- Steering Racks

- Circulating Ball Steering

- Steering Columns

- Pinion Gears

Some symptoms of a failing power steering system include, a vibrating steering wheel, unusual noises when turning, or more effort required when turning.

Call the professionals at Ohio Autocare Hilliard for your auto power steering repair and replacement services. Our trained, certified and experienced mechanics can diagnose the issues quickly and get you back on the road.

Power Steering Repair Services

614-799-8500

Or click the auto shop below for our convenient online scheduling app.

Automobile Power Steering Systems

Before the Ford’s Model T, the first automobiles used tillers to steer the vehicles. Tillers were long poles extending up through the floor board and attached to the front wheel, or wheels, and could be turned by the driver to control the car’s direction. Car tillers were fashioned after water craft navigation devices of the same name. On a boat, a long stick went through the deck floor and was directly attached to the rudder to control directional movement. This worked fine at speeds of 10-20 mph, but struggled as cars got bigger and faster.

Round steering wheels had been used in Europe before the end of the 20th century, but didn’t make an entry into the United States’ market until 1904. The Thomas B. Jeffery Company introduced this feature on their Rambler models, along with left-side driving and the spare tire. Within 10 years, all car manufacturers had transitioned to round steering wheels.

Speeds and weights continued to increase, as did the tire sizes and even the location of the engine, which significantly increased the amount of physical exertion required to turn the steering wheel. Larger diameter steering wheels helped until Chrysler introduced power steering on their 1951 Imperial.

Before the Ford’s Model T, the first automobiles used tillers to steer the vehicles. Tillers were long poles extending up through the floor board and attached to the front wheel, or wheels, and could be turned by the driver to control the car’s direction. Car tillers were fashioned after water craft navigation devices of the same name. On a boat, a long stick went through the deck floor and was directly attached to the rudder to control directional movement. This worked fine at speeds of 10-20 mph, but struggled as cars got bigger and faster.

Round steering wheels had been used in Europe before the end of the 20th century, but didn’t make an entry into the United States’ market until 1904. The Thomas B. Jeffery Company introduced this feature on their Rambler models, along with left-side driving and the spare tire. Within 10 years, all car manufacturers had transitioned to round steering wheels.

Speeds and weights continued to increase, as did the tire sizes and even the location of the engine, which significantly increased the amount of physical exertion required to turn the steering wheel. Larger diameter steering wheels helped until Chrysler introduced power steering on their 1951 Imperial.

HOW POWER STEERING WORKS

When you turn the steering wheel of your vehicle, several components work together to ensure you move in the right direction. There are two main steering systems on the roads today, Recirculating Ball and Rack & Pinion. Rack & Pinion Steering

Rack & Pinion Steering

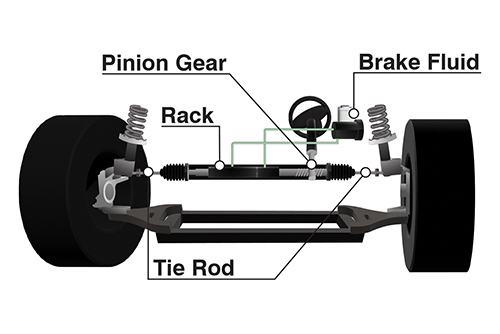

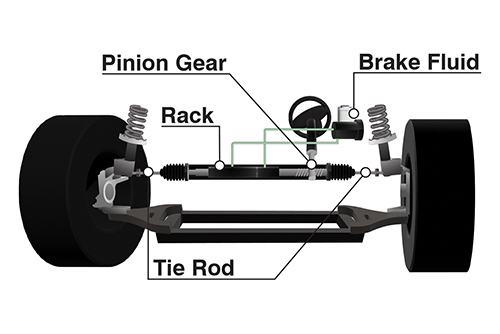

Rack and pinion steering systems have a simple design and extremely lightweight relative to the Recirculating Ball Steering system. In this system, a grooved pinion gear is positioned at the end of the steering column. The pinion gear is attached nearly perpendicular to the steering rack which is grooved or notched to match the pinion gear. The pinion gear moves relative to the steering wheel and that movement is transferred to the steering rack.

Recirculating Ball Steering

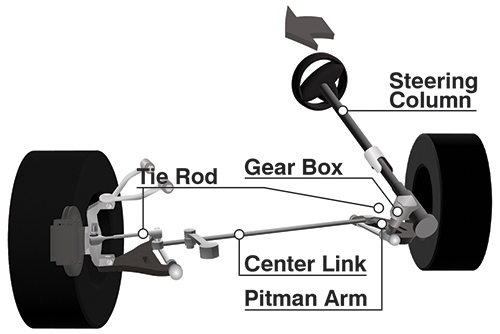

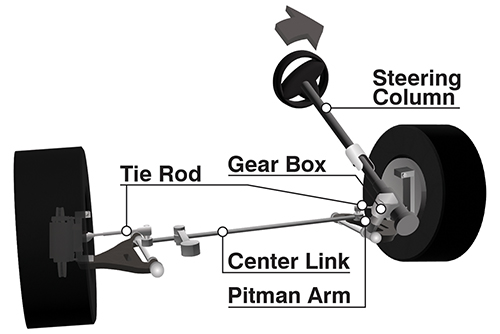

Recirculating Ball Steering systems were standard on most vehicles starting in the 1950’s and can still be found on some consumer vehicles and commercial trucks. In the durable Recirculating Ball Steering system design, the steering column has a threaded steel rod at the end of it and threads into the gear box. Instead of threading directly into the box, similar to a nut and bolt, the threads are spaced far enough to allow ball bearings to stream in between. The Pitman Arm connects the gear box to the Center Link, which has a wheel Tie Rod at either end. The Center Link and Tie Rods move the wheels as the steering column gear box receives inputs from the steering wheel. Before the Ford’s Model T, the first automobiles used tillers to steer the vehicles. Tillers were long poles extending up through the floor board and attached to the front wheel, or wheels, and could be turned by the driver to control the car’s direction. Car tillers were fashioned after water craft navigation devices of the same name. On a boat, a long stick went through the deck floor and was directly attached to the rudder to control directional movement. This worked fine at speeds of 10-20 mph, but struggled as cars got bigger and faster.

Round steering wheels had been used in Europe before the end of the 20th century, but didn’t make an entry into the United States’ market until 1904. The Thomas B. Jeffery Company introduced this feature on their Rambler models, along with left-side driving and the spare tire. Within 10 years, all car manufacturers had transitioned to round steering wheels.

Speeds and weights continued to increase, as did the tire sizes and even the location of the engine, which significantly increased the amount of physical exertion required to turn the steering wheel. Larger diameter steering wheels helped until Chrysler introduced power steering on their 1951 Imperial.

Before the Ford’s Model T, the first automobiles used tillers to steer the vehicles. Tillers were long poles extending up through the floor board and attached to the front wheel, or wheels, and could be turned by the driver to control the car’s direction. Car tillers were fashioned after water craft navigation devices of the same name. On a boat, a long stick went through the deck floor and was directly attached to the rudder to control directional movement. This worked fine at speeds of 10-20 mph, but struggled as cars got bigger and faster.

Round steering wheels had been used in Europe before the end of the 20th century, but didn’t make an entry into the United States’ market until 1904. The Thomas B. Jeffery Company introduced this feature on their Rambler models, along with left-side driving and the spare tire. Within 10 years, all car manufacturers had transitioned to round steering wheels.

Speeds and weights continued to increase, as did the tire sizes and even the location of the engine, which significantly increased the amount of physical exertion required to turn the steering wheel. Larger diameter steering wheels helped until Chrysler introduced power steering on their 1951 Imperial.

HOW A STEERING WHEEL WORKS

When you turn the steering wheel of your vehicle, several components work together to ensure you move in the right direction. There are two main steering systems on the roads today, Recirculating Ball and Rack & Pinion. Rack & Pinion Steering

Rack & Pinion Steering

Rack and pinion steering systems have a simple design and extremely lightweight relative to the Recirculating Ball Steering system. In this system, a grooved pinion gear is positioned at the end of the steering column. The pinion gear is attached nearly perpendicular to the steering rack which is grooved or notched to match the pinion gear. The pinion gear moves relative to the steering wheel and that movement is transferred to the steering rack.

Recirculating Ball Steering

Recirculating Ball Steering systems were standard on most vehicles starting in the 1950’s and can still be found on some consumer vehicles and commercial trucks. In the durable Recirculating Ball Steering system design, the steering column has a threaded steel rod at the end of it and threads into the gear box. Instead of threading directly into the box, similar to a nut and bolt, the threads are spaced far enough to allow ball bearings to stream in between. The Pitman Arm connects the gear box to the Center Link, which has a wheel Tie Rod at either end. The Center Link and Tie Rods move the wheels as the steering column gear box receives inputs from the steering wheel.