Columbus Electrical Systems Repair

OHIO Owned & Operated  CERTIFIED Mechanics

CERTIFIED Mechanics

OHIO Owned & Operated

CERTIFIED Mechanics

Columbus Auto Electrical Systems Repair & Maintenance

Your car’s electrical system is a complex collection of dozens of components spread bumper to bumper throughout the vehicle. With hundreds of feet of wiring coursing throughout the vehicle, the electrical system provides power for everything from door locks to delivering the spark that propels the car forward…or backwards.

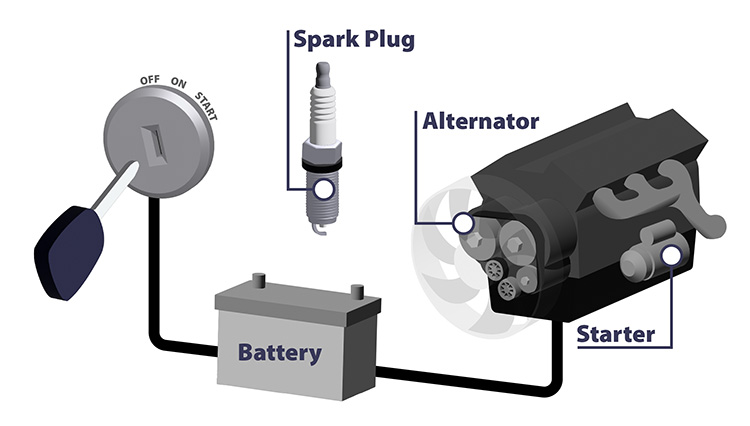

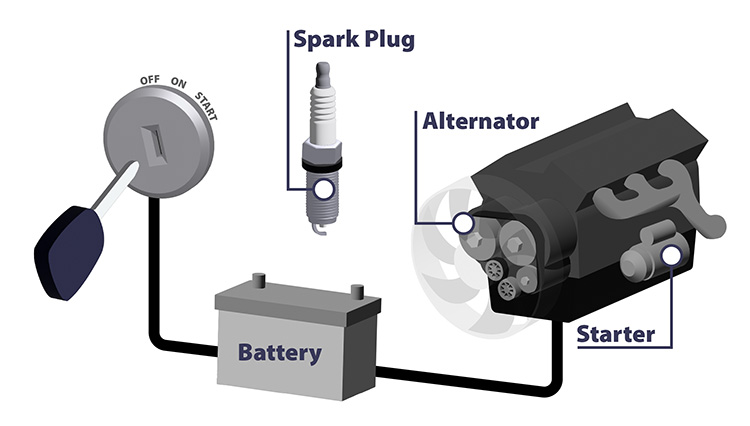

Four of the main components of the electrical system is the battery, starter, alternator, and spark plugs. This system not only powers the electrical components and accessories, but also regenerates energy to re-charge the battery to maximum charge. It also powers modern vehicles computer systems that provide trip and other vehicle information as well as run multiple engine and other component sensors designed for maximum operating efficiency.

Automobile batteries and spark plugs need replaced on a regular basis, but other parts can wear out, like the alternator and starter, from extended wear and tear. Common symptoms of a failing electrical system are dimming or flickering lights, frequent blown fuses, needing frequent jump starts, rough start, or even clicking sounds when starting.

If it’s time for your regular maintenance or you’re experiencing electrical system issues, call the expert mechanics at Ohio Autocare Columbus. We are near the Eastland Mall and can provide a quick diagnostic analysis to pinpoint the issue so we can get you back on the road.

Columbus Electrical System Repair & Service

For family and commercial fleet Electrical Systems Service and Repair, Call Ohio Autocare Columbus at

614-569-3696

or click the auto shop below for our convenient online scheduling app.

Automobile Electrical Systems

AUTOMOBILE ELECTRICAL SYSTEMS

When the automobile was first invented, they didn’t need electrical systems. There were no radios, clocks or power windows. Even the headlights were commonly run with a flammable gas.

Once an engine is started, it’s pretty efficient at running. With all the pistons attached to the crankshaft, the actions of one piston assists the others through their motions. For instance, when the first piston is driven down from the force of the ignited fuel, it’s pushing the second piston into the up position, clearing the exhaust. And so on with each successive piston.

Early automobile engines were typically hand-cranked to get started and a transformer, combined with a magneto (a generator with magnets), provided the spark for the combustion. Other engine starters existed, like gunpowder cylinders, springs, and string pulley systems similar to gasoline lawn mowers. But for each starting system, the goal was to get the engine flywheel turning. Attached to the crankshaft, getting the flywheel turning enabled the engine to turn over and start.

Getting a car started with a hand crank or pulley rope required above average strength which limited ownership to those physically capable. It could also be very dangerous. If the timing was off, the engine could “kick back” (it was still the Horseless Carriage in some parts). This occurred if the spark fired before the piston had fully cycled to the up position, sending the piston backwards, or in reverse. This could result in the hand crank unexpectedly jerking backwards, or the pulley rope being pulled back into the engine.

When the automobile was first invented, they didn’t need electrical systems. There were no radios, clocks or power windows. Even the headlights were commonly run with a flammable gas.

Once an engine is started, it’s pretty efficient at running. With all the pistons attached to the crankshaft, the actions of one piston assists the others through their motions. For instance, when the first piston is driven down from the force of the ignited fuel, it’s pushing the second piston into the up position, clearing the exhaust. And so on with each successive piston.

Early automobile engines were typically hand-cranked to get started and a transformer, combined with a magneto (a generator with magnets), provided the spark for the combustion. Other engine starters existed, like gunpowder cylinders, springs, and string pulley systems similar to gasoline lawn mowers. But for each starting system, the goal was to get the engine flywheel turning. Attached to the crankshaft, getting the flywheel turning enabled the engine to turn over and start.

Getting a car started with a hand crank or pulley rope required above average strength which limited ownership to those physically capable. It could also be very dangerous. If the timing was off, the engine could “kick back” (it was still the Horseless Carriage in some parts). This occurred if the spark fired before the piston had fully cycled to the up position, sending the piston backwards, or in reverse. This could result in the hand crank unexpectedly jerking backwards, or the pulley rope being pulled back into the engine.

Electric Starter Motor

While the English Arnold is credited as the first automobile with an electric starter in 1896, the first patent didn’t materialize in the U.S. until 1903 and didn’t appear on a manufactured vehicle until the 1912 Cadillac Model 30. Spring and air starting systems were alternate technologies available, but by 1920 the electric starter motor was the industry standard. The starter has just one job to do, start the car. It does this by accepting a charge from the battery after the ignition key or button has been engaged. This triggers a pinion gear to mesh with the starter ring of the engine flywheel. Once the flywheel turns, the pinion gear disengages and the starter motor is powered off for the duration of the trip.

Car Battery

Batteries existed prior to the advent of automobile electrical systems, but they were cumbersome, needed frequent charging and didn’t provide enough power to turn the engine flywheel. It wasn’t until 1918 that a 6-volt battery was created with enough power to turn the engine. The 6-volt battery remained the standard until well into the ’50’s when most manufacturers transitioned to 12-volt as engine sizes increased.

Alternator

While the battery does provide some electrical current, an alternator significantly amplifies that charge for enough starting power to get the flywheel turned. Once the engine has started, the extra electricity is used to power other automobile systems, like the headlights, radio, horn, and more. Any electricity left over is returned to restore maximum charge to the battery.

Spark Plug

Delivering that amplified charge to the engine is the spark plug. Each engine cylinder has a dedicated spark plug that delivers its spark after the air and gas mixture has been injected into the cylinder. Spark plugs existed before combustion engines were installed in automobiles with recorded uses back in the early 1800’s.AUTOMOBILE ELECTRICAL SYSTEMS

When the automobile was first invented, they didn’t need electrical systems. There were no radios, clocks or power windows. Even the headlights were commonly run with a flammable gas.

Once an engine is started, it’s pretty efficient at running. With all the pistons attached to the crankshaft, the actions of one piston assists the others through their motions. For instance, when the first piston is driven down from the force of the ignited fuel, it’s pushing the second piston into the up position, clearing the exhaust. And so on with each successive piston.

Early automobile engines were typically hand-cranked to get started and a transformer, combined with a magneto (a generator with magnets), provided the spark for the combustion. Other engine starters existed, like gunpowder cylinders, springs, and string pulley systems similar to gasoline lawn mowers. But for each starting system, the goal was to get the engine flywheel turning. Attached to the crankshaft, getting the flywheel turning enabled the engine to turn over and start.

Getting a car started with a hand crank or pulley rope required above average strength which limited ownership to those physically capable. It could also be very dangerous. If the timing was off, the engine could “kick back” (it was still the Horseless Carriage in some parts). This occurred if the spark fired before the piston had fully cycled to the up position, sending the piston backwards, or in reverse. This could result in the hand crank unexpectedly jerking backwards, or the pulley rope being pulled back into the engine.

When the automobile was first invented, they didn’t need electrical systems. There were no radios, clocks or power windows. Even the headlights were commonly run with a flammable gas.

Once an engine is started, it’s pretty efficient at running. With all the pistons attached to the crankshaft, the actions of one piston assists the others through their motions. For instance, when the first piston is driven down from the force of the ignited fuel, it’s pushing the second piston into the up position, clearing the exhaust. And so on with each successive piston.

Early automobile engines were typically hand-cranked to get started and a transformer, combined with a magneto (a generator with magnets), provided the spark for the combustion. Other engine starters existed, like gunpowder cylinders, springs, and string pulley systems similar to gasoline lawn mowers. But for each starting system, the goal was to get the engine flywheel turning. Attached to the crankshaft, getting the flywheel turning enabled the engine to turn over and start.

Getting a car started with a hand crank or pulley rope required above average strength which limited ownership to those physically capable. It could also be very dangerous. If the timing was off, the engine could “kick back” (it was still the Horseless Carriage in some parts). This occurred if the spark fired before the piston had fully cycled to the up position, sending the piston backwards, or in reverse. This could result in the hand crank unexpectedly jerking backwards, or the pulley rope being pulled back into the engine.

Electric Starter Motor

While the English Arnold is credited as the first automobile with an electric starter in 1896, the first patent didn’t materialize in the U.S. until 1903 and didn’t appear on a manufactured vehicle until the 1912 Cadillac Model 30. Spring and air starting systems were alternate technologies available, but by 1920 the electric starter motor was the industry standard. The starter has just one job to do, start the car. It does this by accepting a charge from the battery after the ignition key or button has been engaged. This triggers a pinion gear to mesh with the starter ring of the engine flywheel. Once the flywheel turns, the pinion gear disengages and the starter motor is powered off for the duration of the trip.

Car Battery

Batteries existed prior to the advent of automobile electrical systems, but they were cumbersome, needed frequent charging and didn’t provide enough power to turn the engine flywheel. It wasn’t until 1918 that a 6-volt battery was created with enough power to turn the engine. The 6-volt battery remained the standard until well into the ’50’s when most manufacturers transitioned to 12-volt as engine sizes increased.

Alternator

While the battery does provide some electrical current, an alternator significantly amplifies that charge for enough starting power to get the flywheel turned. Once the engine has started, the extra electricity is used to power other automobile systems, like the headlights, radio, horn, and more. Any electricity left over is returned to restore maximum charge to the battery.